Jet Engine Transducer For Epr

Exploring the intricacies of jet engine performance monitoring, we delve into the crucial role played by the Engine Pressure Ratio (EPR) transducer. This component is an essential part of modern aircraft engine systems, providing vital data for efficient and safe operations. In this article, we will uncover the significance of EPR transducers, their functioning, and their impact on overall engine performance.

Understanding Engine Pressure Ratio (EPR)

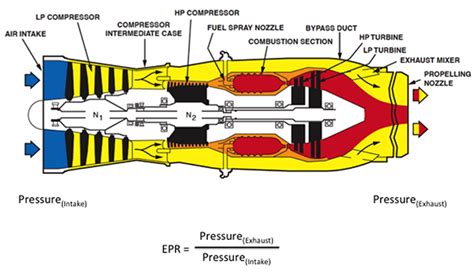

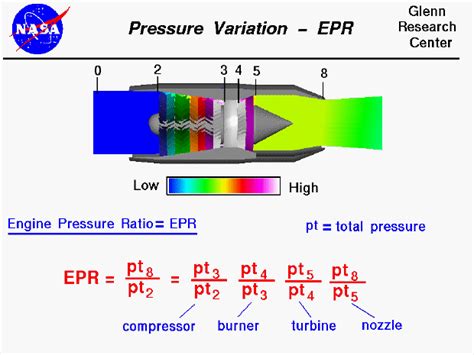

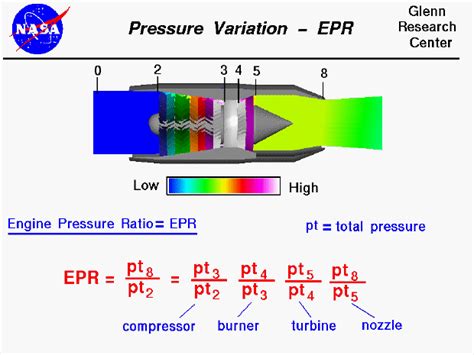

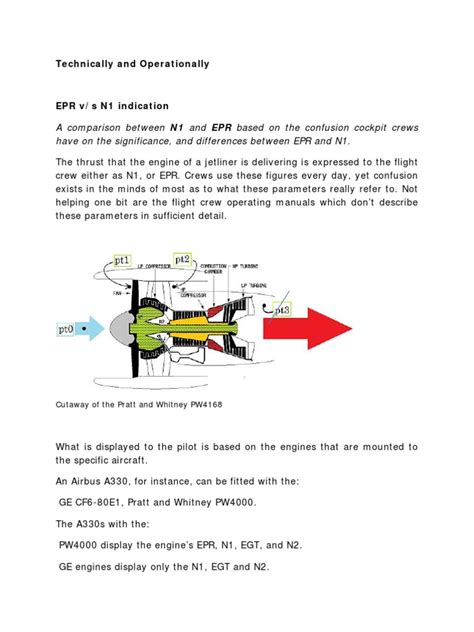

Engine Pressure Ratio, or EPR, is a key parameter in jet engine performance. It represents the ratio of the pressure at the engine's exit to the pressure at the entry, providing an indication of the engine's overall efficiency and power output. EPR is a critical metric used by pilots and engineers to monitor and control engine performance during flight.

The EPR value is influenced by various factors, including engine speed, throttle position, and environmental conditions. By monitoring EPR, pilots can ensure that the engine is operating within its optimal range, maximizing fuel efficiency and minimizing the risk of damage or failure.

The Role of Transducers

Transducers are devices that convert one form of energy into another. In the context of jet engines, transducers are used to measure and convert physical parameters, such as pressure, temperature, and flow rate, into electrical signals. These signals are then transmitted to the engine's control systems for monitoring and analysis.

EPR transducers, in particular, are designed to measure the pressure differential across the engine, providing an accurate representation of the Engine Pressure Ratio. These transducers are typically located at strategic points within the engine, where they can capture precise pressure readings.

Types of EPR Transducers

There are several types of EPR transducers used in jet engines, each with its own advantages and applications:

- Piezoelectric Transducers: These transducers utilize the piezoelectric effect, where certain materials generate an electric charge in response to applied mechanical stress. Piezoelectric transducers are known for their high accuracy and fast response times, making them ideal for dynamic pressure measurements.

- Strain Gauge Transducers: Strain gauge transducers work by measuring the deformation of a diaphragm or strain gauge element due to pressure changes. They are commonly used in applications where high accuracy and stability are required.

- Capacitive Transducers: Capacitive transducers measure pressure by detecting changes in capacitance between two conductive plates. They are known for their linearity and stability, making them suitable for a wide range of pressure measurement applications.

- Vibrating Wire Transducers: Vibrating wire transducers use the principle of wire vibration to measure pressure. The wire's resonance frequency changes with pressure, allowing for accurate pressure measurements. These transducers are often used in harsh environments due to their robustness.

Functioning of EPR Transducers

The functioning of EPR transducers involves several key steps:

- Pressure Sensing: The transducer is positioned at a specific location within the engine, where it comes into contact with the gas flow. As the gas passes through the engine, it exerts pressure on the transducer's sensing element.

- Signal Generation: The sensing element, depending on the type of transducer, generates an electrical signal proportional to the pressure it experiences. This signal is typically in the form of voltage or current.

- Signal Conditioning: The raw electrical signal from the transducer may require conditioning to improve its accuracy and stability. This step involves filtering, amplification, and compensation for any potential errors or drifts.

- Signal Transmission: The conditioned signal is then transmitted to the engine's control systems, often through wired or wireless connections. These systems process the data to calculate the Engine Pressure Ratio and make real-time adjustments as needed.

Benefits of EPR Transducers

The implementation of EPR transducers in jet engines offers several significant advantages:

- Precision Monitoring: EPR transducers provide accurate and real-time measurements of Engine Pressure Ratio, allowing pilots and engineers to closely monitor engine performance. This precision helps in identifying potential issues early on, ensuring prompt maintenance and reducing the risk of in-flight emergencies.

- Enhanced Safety: By continuously monitoring EPR, pilots can ensure that the engine is operating within its safe operating limits. This helps prevent over-speeding or over-stressing the engine, reducing the likelihood of catastrophic failures.

- Fuel Efficiency: Accurate EPR measurements enable pilots to optimize engine performance, resulting in improved fuel efficiency. By maintaining the engine within its optimal range, fuel consumption can be minimized, leading to cost savings and reduced environmental impact.

- Data-Driven Maintenance: The data collected by EPR transducers can be used for predictive maintenance. By analyzing trends and patterns in EPR readings, maintenance teams can anticipate potential issues and schedule maintenance activities proactively, reducing unexpected downtime.

Challenges and Considerations

While EPR transducers offer numerous benefits, there are also challenges and considerations to keep in mind:

- Environmental Factors: Jet engines operate in extreme conditions, including high temperatures and pressures. EPR transducers must be designed to withstand these harsh environments, ensuring their reliability and accuracy.

- Signal Interference: In complex engine systems, there is a risk of signal interference or noise. Proper signal conditioning and shielding techniques are essential to ensure the integrity of the EPR data.

- Calibration and Maintenance: Regular calibration and maintenance of EPR transducers are crucial to maintain their accuracy. Calibration procedures should be followed strictly to ensure consistent and reliable measurements.

- Data Interpretation: Interpreting EPR data requires expertise and understanding of engine performance parameters. Proper training and access to comprehensive data analysis tools are essential for effective decision-making based on EPR readings.

Conclusion

The Engine Pressure Ratio (EPR) transducer is a critical component in modern jet engine systems, playing a vital role in monitoring and controlling engine performance. By providing accurate and real-time measurements of EPR, these transducers enable pilots and engineers to ensure efficient and safe operations. With advancements in transducer technology and data analysis, the future of jet engine performance monitoring looks promising, offering enhanced safety, fuel efficiency, and maintenance capabilities.

Frequently Asked Questions

What is the significance of Engine Pressure Ratio (EPR) in jet engines?

+EPR is a crucial parameter that indicates the efficiency and power output of a jet engine. It helps pilots and engineers monitor and control engine performance, ensuring optimal operation and safety.

How do EPR transducers work?

+EPR transducers measure the pressure differential across the engine, converting it into an electrical signal. This signal is then transmitted to the engine’s control systems for monitoring and analysis.

What are the different types of EPR transducers used in jet engines?

+Common types of EPR transducers include piezoelectric, strain gauge, capacitive, and vibrating wire transducers. Each type has its own advantages and applications.

What are the benefits of using EPR transducers in jet engines?

+EPR transducers offer precise monitoring, enhanced safety, improved fuel efficiency, and data-driven maintenance, making them essential for efficient and reliable jet engine operations.