2. Your Perfect Guide: 7 Steps To Transformer Success Today

Step 1: Understanding Transformers and Their Applications

Transformers are a powerful technology with a wide range of applications. These innovative devices have revolutionized various industries, offering efficient and effective solutions. From enhancing energy transmission to optimizing industrial processes, transformers play a crucial role in modern infrastructure.

Energy Sector:

Transformers are integral to the energy sector, facilitating the transmission and distribution of electricity. By stepping up voltage for long-distance transmission and stepping it down for safe distribution, transformers ensure efficient and reliable power supply.

Industrial Applications:

In industries like manufacturing, transformers are used for various purposes. They regulate voltage for sensitive equipment, power electric motors, and support processes requiring specific voltage levels. Transformers’ versatility makes them indispensable in industrial settings.

Power Generation:

Transformers are essential in power generation, particularly in renewable energy sources like wind and solar. They optimize the output of these renewable systems, ensuring efficient energy conversion and integration into the grid.

Communication Systems:

Transformers also play a vital role in communication systems. They isolate and regulate voltage in telecommunications equipment, ensuring clear and reliable signal transmission.

Step 2: Choosing the Right Transformer for Your Needs

Selecting the appropriate transformer is crucial for optimal performance. Consider factors like voltage requirements, load characteristics, and environmental conditions. Consulting with experts can help determine the best transformer for your specific application.

Voltage Considerations:

Transformers are designed for specific voltage levels. It’s essential to match the transformer’s voltage rating with the application’s requirements to ensure efficient and safe operation.

Load Characteristics:

Understanding the load characteristics, such as power factor and harmonics, is vital. Transformers must be compatible with the load to prevent issues like overheating or voltage instability.

Environmental Factors:

Consider the operating environment, including temperature, humidity, and potential exposure to corrosive elements. Choosing a transformer suitable for the environment ensures reliability and longevity.

Step 3: Installation and Commissioning

Proper installation and commissioning are critical for transformer success. Follow manufacturer guidelines and industry standards to ensure safe and efficient operation.

Site Preparation:

Prepare the installation site by ensuring it meets the transformer’s requirements. This includes proper foundation, ventilation, and accessibility for maintenance.

Connection and Wiring:

Connect the transformer to the electrical system according to the wiring diagram. Use appropriate cables and ensure secure connections to prevent loose contacts or short circuits.

Testing and Commissioning:

Conduct thorough testing to verify the transformer’s performance. This includes insulation resistance tests, polarity checks, and load tests to ensure it meets the required specifications.

Step 4: Maintenance and Care

Regular maintenance is essential to prolong the lifespan and optimize the performance of transformers. Develop a comprehensive maintenance plan to ensure reliability and prevent unexpected failures.

Visual Inspection:

Conduct regular visual inspections to identify any signs of damage, corrosion, or loose connections. Address any issues promptly to prevent further deterioration.

Oil Analysis:

For oil-filled transformers, regular oil analysis is crucial. Monitor parameters like dielectric strength, moisture content, and acidity to detect any abnormalities and take corrective actions.

Cleaning and Cooling:

Keep the transformer clean and free from debris. Ensure proper ventilation and cooling to maintain optimal operating temperatures.

Step 5: Troubleshooting and Fault Diagnosis

Transformers, like any other equipment, may encounter issues. Developing troubleshooting skills and understanding common faults is essential for prompt resolution.

Common Faults:

Familiarize yourself with common transformer faults, such as overheating, insulation failure, or voltage fluctuations. Understand the symptoms and potential causes to facilitate accurate diagnosis.

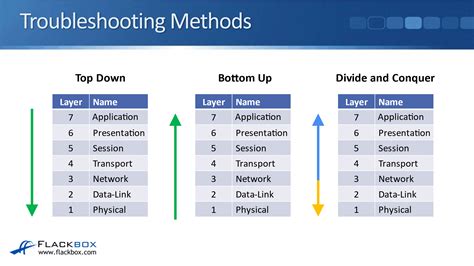

Troubleshooting Techniques:

Develop a systematic approach to troubleshooting. Start with basic checks, such as verifying connections and load conditions, and gradually move to more advanced tests like impedance measurements or partial discharge analysis.

Step 6: Upgrading and Modernization

As technology advances, consider upgrading your transformers to enhance performance and efficiency. Modernization can bring significant benefits, especially in terms of energy savings and reliability.

Energy Efficiency:

Newer transformers often offer higher energy efficiency, reducing operational costs and environmental impact. Upgrading to energy-efficient models can be a cost-effective long-term investment.

Digital Transformation:

Integrating digital technologies, such as condition monitoring systems or smart sensors, can provide real-time data and predictive maintenance capabilities. This enables proactive maintenance and reduces the risk of unexpected failures.

Step 7: Safety Considerations

Transformer safety is of utmost importance. Follow strict safety protocols and guidelines to prevent accidents and ensure the well-being of personnel.

Electrical Safety:

Transformers work with high voltages, so proper electrical safety measures are critical. Ensure proper grounding, use of personal protective equipment (PPE), and adherence to lockout/tagout procedures.

Fire Safety:

Consider the fire safety aspects, especially for oil-filled transformers. Implement fire suppression systems and ensure proper ventilation to minimize the risk of fires.

Training and Awareness:

Provide comprehensive training to personnel involved in transformer operations. Ensure they are aware of potential hazards, emergency procedures, and the proper use of safety equipment.

⚡ Note: Safety should always be a top priority when working with transformers. Always follow industry standards and regulations to ensure a safe working environment.

Conclusion

Transformers are vital components in various industries, offering efficient and reliable solutions. By understanding their applications, selecting the right transformer, and following proper installation, maintenance, and safety practices, you can ensure transformer success. Stay updated with the latest advancements and embrace modernization to maximize the benefits of this powerful technology.

FAQ

What are the benefits of using transformers in the energy sector?

+Transformers play a crucial role in the energy sector by enabling efficient transmission and distribution of electricity. They step up voltage for long-distance transmission, reducing energy losses, and step down voltage for safe distribution to end-users. This ensures a reliable and stable power supply, making transformers essential for modern power grids.

How do I choose the right transformer for my application?

+When selecting a transformer, consider factors such as voltage requirements, load characteristics, and environmental conditions. Consult with experts or refer to industry guidelines to determine the most suitable transformer for your specific application. This ensures optimal performance and avoids potential issues.

What are some common maintenance practices for transformers?

+Regular maintenance is crucial for transformer longevity and performance. Conduct visual inspections to identify any signs of damage or corrosion. For oil-filled transformers, perform oil analysis to monitor parameters like dielectric strength and moisture content. Keep the transformer clean and ensure proper ventilation and cooling to maintain optimal operating temperatures.

How can I troubleshoot transformer issues effectively?

+Familiarize yourself with common transformer faults and their symptoms. Develop a systematic troubleshooting approach, starting with basic checks like verifying connections and load conditions. Gradually progress to more advanced tests, such as impedance measurements or partial discharge analysis, to accurately diagnose and resolve issues.

What are the benefits of upgrading transformers to modern models?

+Upgrading transformers to modern models offers several benefits. Newer transformers often have higher energy efficiency, reducing operational costs and environmental impact. Additionally, integrating digital technologies, such as condition monitoring systems, provides real-time data and predictive maintenance capabilities, enhancing reliability and reducing the risk of unexpected failures.