Why Is Combustion Nonequilibrium

The concept of combustion, a fundamental process that has powered human civilization for centuries, often brings to mind images of roaring fires and the relentless energy they provide. However, beneath this seemingly simple phenomenon lies a complex interplay of chemical reactions and thermodynamics. Understanding the nonequilibrium nature of combustion is crucial for both scientific inquiry and practical applications, from optimizing fuel efficiency in vehicles to designing safer combustion systems.

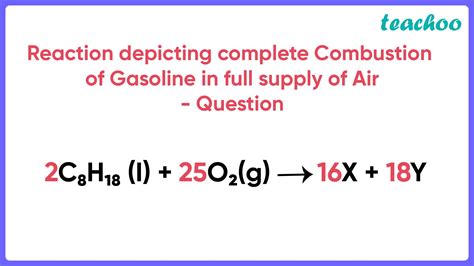

At its core, combustion involves the rapid oxidation of a fuel source, typically in the presence of oxygen. This exothermic reaction releases heat and often light, resulting in the production of combustion products such as carbon dioxide, water vapor, and various pollutants. While the basic principles of combustion are well-established, the intricate details of this process, especially in real-world scenarios, present a challenging puzzle for scientists and engineers.

The Intricacies of Combustion Chemistry

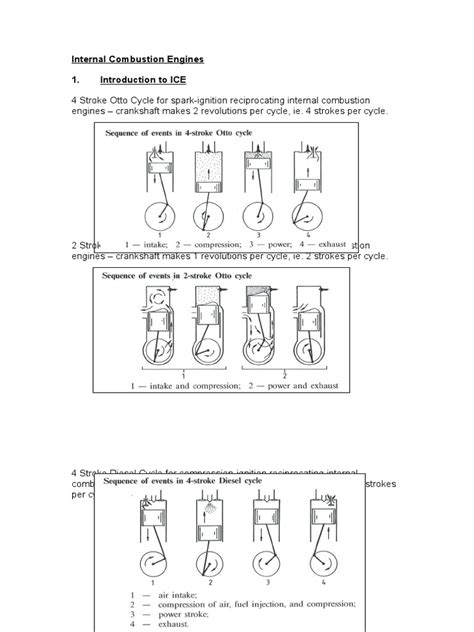

Combustion is a complex chemical process involving a multitude of reactions. The combustion of a fuel, such as gasoline or natural gas, is not a single reaction but a series of interconnected reactions that occur simultaneously. These reactions can be broadly categorized into three stages: ignition, propagation, and extinction.

During ignition, the fuel and oxidizer (usually oxygen) mix and undergo an initial reaction, often initiated by a source of heat or energy. This initial reaction is highly sensitive to temperature and pressure conditions, and it sets off a chain of subsequent reactions. As the combustion process progresses, the reaction rates increase, leading to a self-sustaining reaction known as propagation. Finally, the reaction may reach a point of stability or run out of fuel, leading to extinction.

The complexity of combustion chemistry is further compounded by the variety of fuel types and combustion environments. Different fuels, such as hydrocarbons, alcohols, or even biomass, have unique chemical compositions and reaction mechanisms. Additionally, factors like temperature, pressure, and the presence of catalysts or inhibitors can significantly influence the combustion process.

Thermodynamic Considerations

From a thermodynamic perspective, combustion is a highly exothermic process, meaning it releases a substantial amount of heat. This heat release can be understood through the first law of thermodynamics, which states that energy cannot be created or destroyed, only transferred or converted. In combustion, the chemical energy stored in the fuel is converted into thermal energy, which can be harnessed for various purposes.

However, the efficiency of this energy conversion is not always optimal. In many real-world combustion scenarios, such as internal combustion engines or industrial furnaces, a significant portion of the energy is lost as waste heat. This inefficiency is a result of the nonequilibrium nature of combustion, where the system is constantly changing and far from a state of thermodynamic equilibrium.

In an idealized equilibrium state, the temperatures and pressures of the reactants and products would be uniform throughout the system. However, in reality, combustion processes are dynamic and often involve rapid, localized changes in temperature and pressure. These variations can lead to inefficiencies, such as incomplete combustion, where not all the fuel is fully oxidized, resulting in the production of pollutants like carbon monoxide.

The Role of Turbulence and Mixing

One of the key factors contributing to the nonequilibrium nature of combustion is the presence of turbulence and mixing. In many practical combustion systems, such as jet engines or boilers, the fuel and oxidizer are mixed and burned in a turbulent flow regime. Turbulence is characterized by chaotic, irregular fluid motion, which can enhance mixing and promote more efficient combustion.

However, turbulence also introduces complexities. It can lead to variations in temperature and pressure within the combustion zone, affecting the reaction rates and product distribution. Additionally, turbulence can cause local hotspots, where the temperature is significantly higher than the average, leading to potential issues like flameholding or thermal NOx formation.

To optimize combustion efficiency and minimize pollutants, engineers often employ various strategies to control and manage turbulence. This includes the design of combustion chambers, the use of injectors or nozzles to enhance mixing, and the introduction of catalysts or additives to promote specific reactions.

The Challenge of Pollutant Formation

One of the most significant challenges in combustion engineering is the formation of pollutants. These pollutants, such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter, are often byproducts of incomplete or inefficient combustion. They not only contribute to environmental issues like air pollution and climate change but also have health implications.

The formation of pollutants is intricately linked to the nonequilibrium nature of combustion. In an ideal equilibrium state, the reaction conditions would be uniform, and the products would be well-defined. However, in real-world combustion scenarios, variations in temperature, pressure, and mixing can lead to the formation of undesirable byproducts.

For example, high temperatures and pressures can promote the formation of NOx through the Zeldovich mechanism. On the other hand, low temperatures and incomplete mixing can result in the production of CO, a toxic gas. Managing these pollutant formation pathways is a critical aspect of combustion engineering, and it often involves a delicate balance between efficiency and emissions control.

Advancements in Combustion Technology

Understanding the nonequilibrium nature of combustion has driven significant advancements in combustion technology. Researchers and engineers have developed various strategies to optimize combustion processes, improve efficiency, and reduce pollutant emissions.

One approach is the use of advanced combustion concepts, such as lean burn or premixed combustion. These techniques aim to control the combustion process by carefully managing the fuel-air mixture and reaction conditions. By operating at lean fuel-air ratios or premixing the fuel and air before combustion, these methods can reduce the formation of pollutants and improve overall efficiency.

Another area of focus is the development of advanced combustion systems, such as homogeneous charge compression ignition (HCCI) engines. HCCI engines combine the advantages of both gasoline and diesel engines, offering high efficiency and low emissions. By carefully controlling the combustion process through precise timing and fuel injection, HCCI engines can achieve near-ideal combustion conditions, reducing pollutant formation and improving fuel efficiency.

Conclusion

In conclusion, the nonequilibrium nature of combustion is a fascinating and complex aspect of this ubiquitous process. From the intricate chemistry of fuel oxidation to the challenges of pollutant formation and thermodynamic inefficiencies, combustion presents a rich field of study for scientists and engineers. By unraveling the intricacies of combustion, we can continue to develop more efficient, cleaner, and safer combustion technologies, shaping a more sustainable future.

What is the main difference between equilibrium and nonequilibrium combustion?

+Equilibrium combustion occurs when the temperatures and pressures of the reactants and products are uniform throughout the system, resulting in well-defined products. In contrast, nonequilibrium combustion involves dynamic and often localized changes in temperature and pressure, leading to variations in reaction rates and product distribution.

How does turbulence affect combustion efficiency?

+Turbulence can enhance mixing and promote more efficient combustion by increasing the contact between the fuel and oxidizer. However, it can also lead to variations in temperature and pressure, affecting reaction rates and potentially causing local hotspots, which can impact efficiency and pollutant formation.

What are some strategies to reduce pollutant emissions in combustion processes?

+To reduce pollutant emissions, engineers can employ various strategies such as lean burn or premixed combustion, which carefully control the fuel-air mixture and reaction conditions. Additionally, the use of advanced combustion systems like HCCI engines can achieve near-ideal combustion conditions, minimizing pollutant formation.