Hydraulic Cylinder Seal Kit Catalog

Hydraulic cylinders are essential components in various industrial applications, providing linear motion and force transmission. To ensure the smooth operation and longevity of these cylinders, regular maintenance and the use of high-quality seal kits are crucial. This blog post will delve into the world of hydraulic cylinder seal kits, exploring their significance, types, and how to choose the right kit for your specific needs.

Understanding Hydraulic Cylinder Seal Kits

Hydraulic cylinder seal kits are comprehensive collections of seals and related components designed to repair and maintain hydraulic cylinders. These kits are vital as they ensure the integrity of the cylinder's sealing system, preventing leaks and maintaining optimal performance.

The Importance of Seal Kits

- Leak Prevention: Seal kits prevent fluid leakage, maintaining the pressure and efficiency of the hydraulic system.

- Performance Enhancement: By replacing worn-out seals, you can improve the cylinder's performance and reduce energy consumption.

- Extended Lifespan: Regular maintenance with seal kits prolongs the life of hydraulic cylinders, reducing the need for frequent replacements.

- Cost-Effectiveness: Investing in seal kits is more economical than replacing the entire cylinder, especially for larger industrial applications.

Types of Hydraulic Cylinder Seal Kits

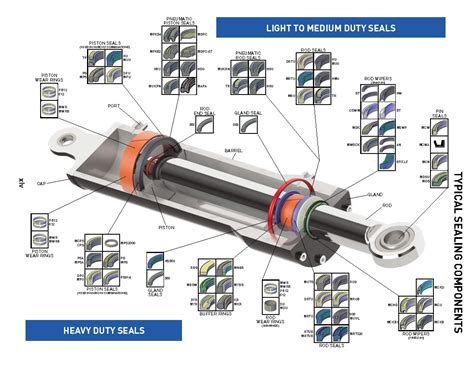

Hydraulic cylinder seal kits come in various types, each designed for specific cylinder configurations and applications. Understanding the different types is crucial to selecting the right kit for your needs.

Standard Seal Kits

Standard seal kits are the most common and versatile option. They typically include a range of seals, such as rod seals, piston seals, and wear bands, suitable for most hydraulic cylinder applications. These kits are ideal for general maintenance and repairs.

Custom Seal Kits

Custom seal kits are tailored to specific cylinder designs and requirements. They are often used in specialized industries or for unique cylinder configurations. Custom kits ensure a perfect fit and optimal performance for your specific application.

Seal Kits for Specific Applications

Some seal kits are designed for specific industries or applications. For example, there are seal kits for mobile equipment, heavy-duty construction machinery, or even food and beverage processing equipment. These kits may include additional components or materials suitable for the application's unique demands.

Choosing the Right Seal Kit

Selecting the appropriate seal kit is crucial for effective maintenance and repair. Consider the following factors when choosing a hydraulic cylinder seal kit:

Cylinder Type and Size

Ensure the seal kit is compatible with your cylinder's type and size. Different cylinders have unique sealing requirements, so it's essential to match the kit to your specific cylinder.

Operating Conditions

Take into account the operating conditions of your hydraulic system. Factors such as pressure, temperature, and fluid type can influence the choice of seals. Some seals are better suited for high-pressure applications, while others excel in extreme temperature environments.

Seal Material

The material of the seals is critical. Common seal materials include polyurethane (PU), nitrile rubber (NBR), and fluorocarbon (FKM). Each material has unique properties, offering resistance to specific chemicals, temperatures, and pressures. Choose a material that aligns with your application's requirements.

Seal Kit Manufacturer

Consider the reputation and quality of the seal kit manufacturer. Reputable manufacturers often provide detailed specifications and ensure consistent quality, making it easier to find the right kit for your needs.

Installation and Maintenance Tips

Proper installation and maintenance of hydraulic cylinder seal kits are essential for their effectiveness and longevity. Here are some tips to consider:

Cleanliness

Maintain a clean work area during installation to prevent contamination of the seals. Use clean tools and ensure the cylinder is free from debris and old seals before installing the new kit.

Seal Lubrication

Some seals require lubrication to function optimally. Follow the manufacturer's instructions for the appropriate type and amount of lubricant to apply.

Seal Installation Technique

Proper installation technique is crucial. Ensure the seals are aligned correctly and seated properly. Avoid over-tightening or under-tightening components, as this can lead to seal failure.

Regular Maintenance

Schedule regular maintenance checks to inspect the seals and identify any potential issues. Early detection of seal wear can prevent major failures and extend the life of your hydraulic cylinder.

Common Seal Kit Issues and Solutions

While hydraulic cylinder seal kits are designed for reliable performance, issues can arise. Here are some common problems and their solutions:

Leakage

If you notice leakage after installing a new seal kit, check for proper seal installation and alignment. Ensure there are no damaged or missing components. In some cases, a different seal material or design may be required to address the leakage issue.

Seal Wear

Seal wear is a common issue, especially in high-cycle applications. Regularly inspect the seals for signs of wear, such as cracks or deformation. Replace worn-out seals promptly to prevent further damage.

Contamination

Contamination of the hydraulic fluid can lead to seal damage. Ensure proper filtration and maintain clean fluid to prevent contamination-related issues. Regularly change the hydraulic fluid as recommended by the manufacturer.

Table: Common Seal Kit Components

| Component | Description |

|---|---|

| Rod Seals | Seals located on the cylinder rod, preventing fluid leakage. |

| Piston Seals | Seals that ride on the cylinder wall, ensuring smooth movement and preventing fluid bypass. |

| Wear Bands | Wear-resistant bands that protect the cylinder walls and guide the piston. |

| O-Rings | Small circular seals used for static and dynamic sealing applications. |

| Wiper Seals | Seals that wipe away contaminants and prevent debris from entering the cylinder. |

🛠️ Note: Always refer to the manufacturer's instructions and guidelines for specific installation and maintenance procedures.

Conclusion

Hydraulic cylinder seal kits are an essential component of maintenance and repair for hydraulic systems. By understanding the different types of seal kits, their importance, and how to choose the right one, you can ensure the optimal performance and longevity of your hydraulic cylinders. Regular maintenance, proper installation, and prompt attention to seal-related issues are key to keeping your hydraulic systems running smoothly.

How often should I replace hydraulic cylinder seals?

+The frequency of seal replacement depends on various factors, including operating conditions, cycle count, and fluid quality. As a general guideline, it is recommended to inspect seals regularly and replace them when signs of wear or damage are evident. In high-cycle applications, seals may need replacement more frequently.

Can I use a standard seal kit for all hydraulic cylinders?

+While standard seal kits are versatile, they may not be suitable for all cylinder types and applications. It is crucial to select a seal kit that matches your cylinder’s specifications and operating conditions. Custom seal kits may be required for specialized cylinders or unique applications.

What are the signs of a worn-out seal in a hydraulic cylinder?

+Signs of a worn-out seal include visible cracks, deformation, or excessive wear on the seal’s surface. Additionally, you may notice increased leakage, reduced cylinder performance, or abnormal noise during operation. Regular inspection and prompt replacement of worn-out seals are essential to prevent further damage.