Generate 5 Amazing Lasers Now: An Expert's Guide

In the world of lasers, there's an incredible array of options to explore, each with its own unique capabilities and applications. From powerful industrial tools to compact handheld devices, lasers have revolutionized various industries and our daily lives. In this blog post, we'll dive into the fascinating world of lasers, uncovering five amazing types that showcase the versatility and impact of this technology. Get ready to be amazed as we explore the power and precision of these cutting-edge devices!

1. CO2 Lasers: Precision Cutting and Engraving

CO2 lasers are renowned for their exceptional precision and versatility. These lasers emit an invisible infrared beam, making them ideal for cutting and engraving a wide range of materials, including wood, acrylic, glass, and even some metals. With their high power and accuracy, CO2 lasers are widely used in industries such as manufacturing, woodworking, and signage production.

One of the key advantages of CO2 lasers is their ability to create intricate designs and patterns with exceptional detail. Whether it's engraving a personalized message on a gift or cutting intricate shapes for architectural models, CO2 lasers deliver exceptional results. Additionally, their non-contact nature ensures minimal material deformation, making them perfect for delicate and precise tasks.

Note: CO2 lasers are commonly used in laser cutting machines, allowing for automated and precise cutting and engraving processes.

Note: CO2 lasers are commonly used in laser cutting machines, allowing for automated and precise cutting and engraving processes.

2. Fiber Lasers: Industrial Powerhouses

Fiber lasers have revolutionized the industrial sector with their incredible power and efficiency. These lasers utilize a fiber optic cable to deliver a highly concentrated beam of light, making them ideal for applications that require high energy and precision. Fiber lasers are commonly used in metal cutting, welding, and marking, offering exceptional speed, accuracy, and consistency.

One of the standout features of fiber lasers is their ability to process a wide range of metal materials, including steel, aluminum, and stainless steel. With their high peak power and exceptional beam quality, fiber lasers can achieve deep penetration and clean cuts, making them indispensable in manufacturing and automotive industries. Additionally, their compact size and low maintenance requirements make them a popular choice for industrial applications.

Note: Fiber lasers are known for their exceptional beam quality, resulting in precise and clean cuts, making them highly efficient for industrial applications.

3. Diode Lasers: Compact and Versatile

Diode lasers have gained popularity for their compact size and versatility. These lasers are commonly used in consumer electronics, medical devices, and telecommunications. With their small form factor and low power consumption, diode lasers offer a wide range of applications, from laser pointers and barcode scanners to medical equipment and optical communications.

One of the key advantages of diode lasers is their affordability and ease of integration into various devices. They are commonly used in laser printers, DVD players, and even in medical procedures such as laser hair removal and dermatology. Diode lasers are also known for their long lifespan and reliability, making them a preferred choice for applications that require durability and precision.

Note: Diode lasers are available in different wavelengths, allowing for specific applications such as infrared or visible light communication.

4. Nd:YAG Lasers: Versatile and Powerful

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers are known for their versatility and power. These lasers emit an intense beam of light in the near-infrared spectrum, making them suitable for a wide range of applications. Nd:YAG lasers are commonly used in industries such as automotive, aerospace, and electronics for welding, cutting, and marking.

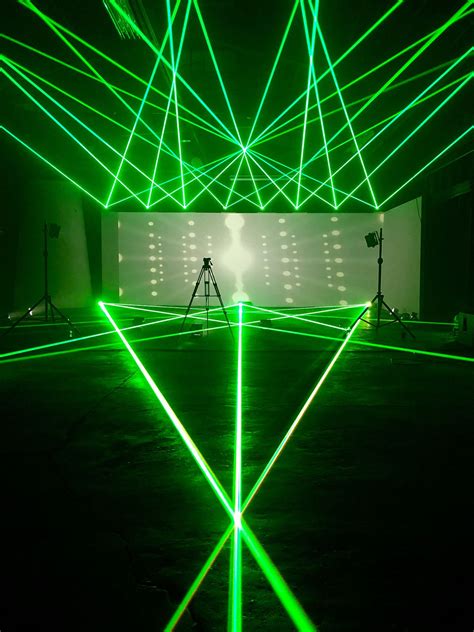

One of the standout features of Nd:YAG lasers is their ability to achieve high peak power and excellent beam quality. This makes them ideal for precision cutting and welding of metals, as well as for medical applications such as laser surgery and dermatological procedures. Nd:YAG lasers are also commonly used in laser shows and entertainment, creating stunning visual effects with their bright and powerful beams.

Note: Nd:YAG lasers can be operated in both continuous wave (CW) and pulsed modes, allowing for flexibility in power output and application requirements.

5. UV Lasers: Precision Micro-Machining

UV (Ultraviolet) lasers are renowned for their precision and ability to work with delicate materials. These lasers emit a beam of light in the ultraviolet spectrum, making them ideal for micro-machining and fine detailing. UV lasers are commonly used in the electronics industry for precise cutting, drilling, and marking of small components.

One of the key advantages of UV lasers is their ability to achieve extremely high precision and accuracy. With their short wavelength, UV lasers can create intricate patterns and fine details on a microscopic scale. This makes them indispensable in the production of microelectronics, such as integrated circuits and semiconductor devices. UV lasers are also used in medical applications, such as dentistry and ophthalmology, for precise and delicate procedures.

Note: UV lasers require specialized safety measures due to their high energy and potential hazards associated with ultraviolet radiation.

Conclusion

Lasers have undoubtedly become an integral part of our modern world, with their incredible versatility and precision. From the powerful CO2 and fiber lasers used in industrial applications to the compact and versatile diode lasers, each type of laser brings its own unique capabilities. Whether it's cutting, engraving, welding, or micro-machining, lasers have revolutionized various industries and continue to push the boundaries of what's possible.

As technology advances, we can expect even more innovative laser applications to emerge, further enhancing our lives and shaping the future. So, the next time you encounter a laser, remember the incredible power and precision that lies within these remarkable devices.

What are the key differences between CO2 and fiber lasers?

+CO2 lasers are known for their versatility and precision in cutting and engraving various materials, while fiber lasers are renowned for their high power and efficiency in industrial applications such as metal cutting and welding. CO2 lasers emit an invisible infrared beam, while fiber lasers utilize a fiber optic cable for beam delivery.

How do diode lasers differ from other laser types?

+Diode lasers stand out for their compact size, affordability, and versatility. They are commonly used in consumer electronics and telecommunications due to their low power consumption and ease of integration. Diode lasers are available in different wavelengths, making them suitable for various applications.

What are the advantages of Nd:YAG lasers over other laser types?

+Nd:YAG lasers offer a unique combination of power and versatility. They are capable of achieving high peak power and excellent beam quality, making them suitable for a wide range of applications, including welding, cutting, and medical procedures. Nd:YAG lasers can operate in both continuous wave and pulsed modes, providing flexibility in power output.

How are UV lasers used in the medical field?

+UV lasers are utilized in the medical field for precise and delicate procedures. They are commonly used in dentistry for procedures such as cavity preparation and in ophthalmology for laser eye surgery. UV lasers offer extremely high precision and accuracy, making them ideal for micro-machining and fine detailing.

What safety measures should be considered when working with lasers?

+When working with lasers, it is crucial to prioritize safety. This includes wearing appropriate eye and skin protection, ensuring proper ventilation, and following manufacturer guidelines. It is important to understand the specific hazards associated with the type of laser being used and take necessary precautions to prevent accidents or injuries.