Design Your Dodge 318 Engine: Ultimate Guide

Welcome to the ultimate guide on designing and building your very own Dodge 318 engine! Whether you're a car enthusiast, a DIY mechanic, or someone looking to take on a challenging project, this comprehensive guide will walk you through the process step by step. By the end of this journey, you'll have the knowledge and skills to create a powerful and reliable engine that's tailored to your needs.

Understanding the Dodge 318 Engine

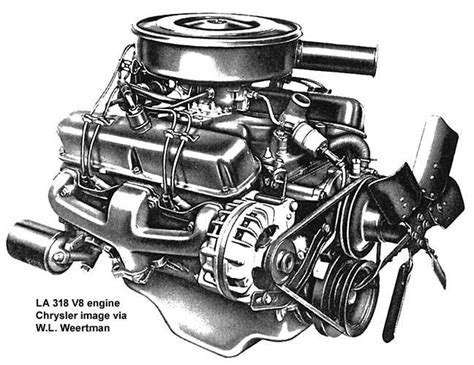

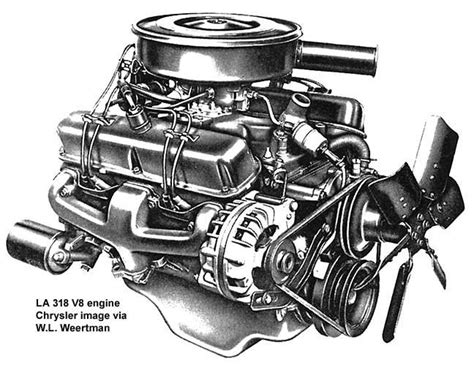

The Dodge 318 engine, also known as the Chrysler 318 or the LA engine, is a V8 powerhouse that has been a staple in the automotive world for decades. With its robust design and versatility, it has powered a wide range of vehicles, from classic muscle cars to modern-day trucks. Let's delve into the key components and characteristics that make this engine a popular choice among enthusiasts.

Engine Architecture

The Dodge 318 engine belongs to the family of Chrysler's small-block V8 engines, renowned for their reliability and performance. It features a V-shaped design with eight cylinders arranged in two banks, creating a powerful and efficient combustion system. With a displacement of 318 cubic inches (5.2 liters), this engine delivers an impressive balance of power and fuel efficiency.

Key Specifications

- Displacement: 318 cubic inches (5.2 liters)

- Cylinder Configuration: V8

- Bore and Stroke: 3.88 x 3.31 inches

- Compression Ratio: 8.5:1 to 9.5:1

- Horsepower: Varies based on year and modifications (typically 140-250 hp)

- Torque: Varies based on year and modifications (typically 240-300 lb-ft)

Advantages of the Dodge 318 Engine

- Versatility: It can be found in a wide range of vehicles, making it a popular choice for customization and restoration projects.

- Reliability: Known for its durability and longevity, making it a trusted option for daily drivers and long-distance travels.

- Modifiability: The engine's design allows for easy modifications, enabling enthusiasts to enhance its performance and achieve their desired power output.

Step 1: Planning and Research

Before diving into the build process, it's crucial to have a well-thought-out plan and conduct thorough research. This step will set the foundation for a successful engine design and ensure that you make informed decisions along the way.

Define Your Goals

Determine the purpose of your Dodge 318 engine build. Are you aiming for maximum power and performance, or do you prioritize fuel efficiency and reliability? Understanding your goals will guide your choices throughout the design process.

Research and Learn

- Study the history and evolution of the Dodge 318 engine. Familiarize yourself with its various iterations and the changes made over the years.

- Explore online forums, blogs, and communities dedicated to engine building and restoration. Engage with experienced enthusiasts who can provide valuable insights and advice.

- Read technical manuals, guides, and books that offer detailed information on engine design, maintenance, and troubleshooting.

Gather Information

Collect relevant data and specifications for your specific engine model. This includes dimensions, power output, torque curves, and any known weaknesses or common issues associated with your engine type.

Step 2: Sourcing Components

With a solid plan in place, it's time to source the components needed to build your Dodge 318 engine. This step requires careful consideration to ensure you acquire high-quality parts that align with your design goals.

Engine Block

- Choose a reputable engine block manufacturer or supplier. Look for blocks made from durable materials like cast iron or aluminum, ensuring strength and longevity.

- Consider the block's bore and stroke dimensions to match your desired displacement and power output.

- Inspect the block for any signs of damage or wear. It's crucial to start with a solid foundation for a successful build.

Crankshaft and Connecting Rods

- Select a crankshaft that matches your engine's bore and stroke specifications. Ensure it is balanced and aligned with your performance goals.

- Choose high-quality connecting rods made from durable materials like forged steel or aluminum. These rods should be strong enough to withstand the engine's power and torque.

Cylinder Heads

- Opt for cylinder heads that offer the airflow and combustion characteristics you desire. Consider factors like port size, valve angles, and combustion chamber design.

- For performance builds, consider investing in ported and polished heads or even custom-designed heads to optimize airflow and enhance power output.

Camshaft

- Choose a camshaft that aligns with your engine's intended use. For street-driven engines, a mild camshaft with good low-end torque and drivability is often preferred.

- If you're building a high-performance engine, consult camshaft manufacturers or specialists to select a camshaft with the ideal lift, duration, and lobe separation for your specific application.

Valvetrain Components

- Select high-quality valves, springs, retainers, and locks to ensure reliable and efficient valve operation.

- Consider upgrading to lightweight titanium valves for reduced reciprocating mass and improved high-rpm performance.

Pistons and Rings

- Choose pistons that match your engine's bore and stroke dimensions. Consider factors like compression ratio, piston material (usually aluminum or forged steel), and piston-to-wall clearance.

- Select high-quality piston rings with the appropriate tension and profile to ensure proper sealing and reduce blow-by.

Additional Components

Don't forget to source other essential components like oil pump, timing set, bearings, gaskets, and any custom parts required for your specific build.

Step 3: Engine Assembly

Now that you have all the necessary components, it's time to assemble your Dodge 318 engine. This step requires precision, attention to detail, and a systematic approach to ensure a flawless build.

Block Preparation

- Clean and inspect the engine block, removing any dirt, grease, or debris.

- Check for any signs of damage or wear, and address any issues before proceeding.

- Prepare the block for assembly by installing main bearing caps, aligning them with the proper torque specifications.

Crankshaft Installation

- Insert the crankshaft into the engine block, ensuring proper alignment and fit.

- Install the main bearings and torque them to the manufacturer's specifications.

- Secure the crankshaft in place using the appropriate bolts or fasteners.

Connecting Rods and Pistons

- Prepare the connecting rods by installing the bearings and aligning them with the crankshaft journals.

- Slide the pistons onto the connecting rods, ensuring proper alignment and fit.

- Install the piston rings, paying attention to the correct orientation and placement.

Cylinder Head Installation

- Clean and inspect the cylinder heads, ensuring they are free from any defects or damage.

- Install the head gaskets, aligning them precisely with the engine block.

- Secure the cylinder heads to the block using the appropriate bolts and torque them to the specified values.

Valvetrain Assembly

- Install the camshaft, ensuring proper alignment and fit within the engine block.

- Assemble the valvetrain components, including valves, springs, retainers, and locks.

- Adjust the valve lash (clearance) according to the manufacturer's recommendations.

Accessory Components

- Install the oil pump, ensuring proper alignment and fit.

- Connect the timing set and ensure the engine's timing is set accurately.

- Mount the intake manifold and carburetor or fuel injection system, depending on your chosen setup.

Step 4: Engine Break-In and Testing

After assembling your Dodge 318 engine, it's crucial to perform a proper break-in process to ensure the longevity and reliability of your build. This step involves running the engine under controlled conditions to seat the piston rings and lubricate the moving parts effectively.

Break-In Procedure

- Start the engine and let it idle for a few minutes to stabilize the oil pressure.

- Rev the engine gently, keeping the RPMs below 3000 for the first 50 miles.

- Gradually increase the RPMs and engine load over the next 50-100 miles, avoiding sudden acceleration or high-RPM operation.

- After the initial break-in period, continue to operate the engine within its recommended RPM range for the next 500-1000 miles.

Testing and Tuning

- Conduct a compression test to ensure all cylinders are within an acceptable range.

- Check for any leaks or abnormal noises during engine operation.

- Tweak the carburetor or fuel injection settings to optimize fuel delivery and performance.

- Monitor the engine's temperature and oil pressure to ensure they remain within safe limits.

Step 5: Final Adjustments and Upgrades

Once your Dodge 318 engine has undergone the break-in process and initial testing, it's time to fine-tune and upgrade various components to achieve your desired performance and reliability.

Ignition System

- Upgrade to a high-performance ignition system with improved spark timing and energy.

- Consider installing an aftermarket ignition coil or a distributor with an adjustable advance curve.

Exhaust System

- Choose an exhaust system that complements your engine's power output and sound preferences.

- Select headers or exhaust manifolds that offer improved airflow and scavenging for better performance.

Cooling System

- Ensure your engine's cooling system is adequately sized and capable of handling the increased heat generated by your modified engine.

- Consider upgrading to a high-performance radiator or installing an additional electric fan for improved cooling efficiency.

Engine Management System

- For more advanced builds, consider installing an aftermarket engine management system (EMS) to optimize fuel delivery, ignition timing, and other parameters.

- EMS systems offer precise control over engine performance and can be tuned to your specific needs.

Step 6: Maintenance and Longevity

Proper maintenance is key to ensuring the longevity and reliability of your Dodge 318 engine. Regular inspections, oil changes, and attention to potential issues will keep your engine running smoothly for years to come.

Regular Maintenance

- Follow the manufacturer's recommended maintenance schedule for oil changes, filter replacements, and other routine tasks.

- Inspect the engine regularly for any signs of leaks, unusual noises, or performance issues.

- Keep an eye on the engine's temperature and oil pressure, addressing any anomalies promptly.

Potential Issues and Troubleshooting

- Common issues include oil leaks, coolant leaks, misfires, and engine overheating.

- Troubleshoot and address these issues promptly to prevent further damage or complications.

Conclusion

Building your Dodge 318 engine is an exciting and rewarding journey that requires dedication, attention to detail, and a passion for automotive craftsmanship. By following this comprehensive guide, you'll have the knowledge and tools to design and construct a powerful and reliable engine that meets your specific needs. Remember to approach each step with care and seek expert advice when needed. Happy building, and may your Dodge 318 engine roar with pride and performance!

FAQ

How long does it take to build a Dodge 318 engine from scratch?

+The time required to build a Dodge 318 engine can vary greatly depending on your experience, the complexity of your build, and the availability of components. On average, it can take anywhere from a few weeks to several months to complete the entire process, including planning, sourcing parts, assembly, and testing.

Can I use aftermarket parts for my Dodge 318 engine build?

+Absolutely! Aftermarket parts offer a wide range of options for customization and performance upgrades. From cylinder heads and camshafts to pistons and valvetrain components, there are numerous reputable aftermarket manufacturers that cater to the Dodge 318 engine. However, it’s important to choose high-quality parts that are compatible with your specific engine model and intended use.

What is the recommended compression ratio for a high-performance Dodge 318 engine?

+The recommended compression ratio for a high-performance Dodge 318 engine can vary depending on factors such as the intended power output, fuel type, and ignition system. Generally, compression ratios ranging from 9.5:1 to 11:1 are commonly used for performance builds. It’s important to consult with engine builders or specialists to determine the optimal compression ratio for your specific application.

Can I use a Dodge 318 engine in a non-Dodge vehicle?

+Absolutely! The Dodge 318 engine is a versatile powerhouse that can be used in a wide range of vehicles beyond Dodge models. Its compatibility with various transmission and drivetrain setups makes it a popular choice for engine swaps and custom builds. However, it’s crucial to ensure proper mounting, drivetrain compatibility, and any necessary modifications to accommodate the engine in your chosen vehicle.

What are some common modifications for a Dodge 318 engine?

+There are numerous modifications you can make to enhance the performance and power output of your Dodge 318 engine. Some common modifications include upgrading the camshaft, cylinder heads, and intake manifold. Installing performance exhaust systems, improving the fuel delivery system, and upgrading the ignition system can also significantly boost performance. Additionally, adding a supercharger or turbocharger can take your engine’s power to the next level.