Biobased Foams Reduce Petroleum Use

The world is gradually transitioning towards more sustainable practices, and one significant area of focus is reducing our reliance on petroleum-based products. In this blog post, we will explore the benefits and applications of biobased foams, which offer an eco-friendly alternative to traditional petroleum-derived foams.

Understanding Biobased Foams

Biobased foams, as the name suggests, are derived from biological sources rather than fossil fuels. These foams are manufactured using renewable resources such as plant-based oils, starches, and natural fibers. The concept behind biobased materials is to minimize the environmental impact associated with the production and disposal of traditional petroleum-based products.

One of the key advantages of biobased foams is their ability to reduce our carbon footprint. Unlike petroleum-based foams, which contribute to greenhouse gas emissions during production and release toxic chemicals upon disposal, biobased foams have a lower environmental impact throughout their lifecycle.

Environmental Benefits

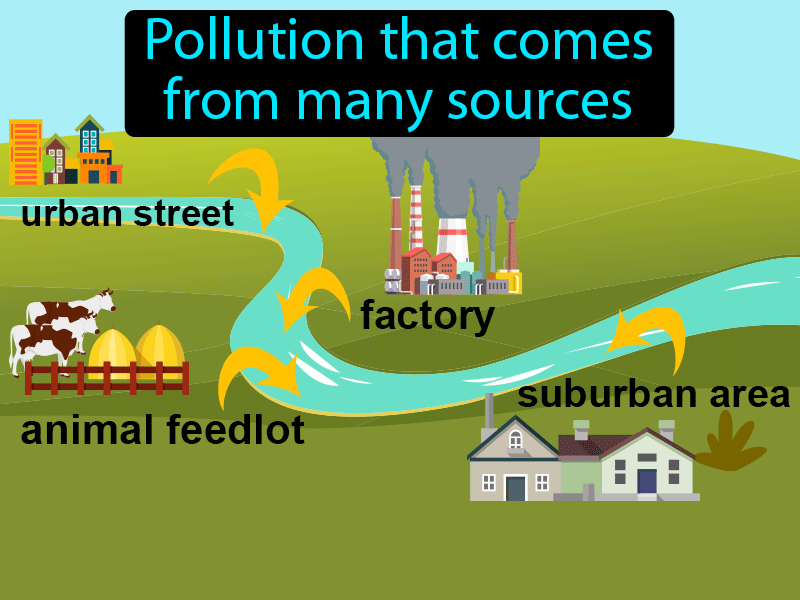

The environmental advantages of biobased foams are numerous. Firstly, they help conserve non-renewable resources by reducing the demand for petroleum. This is especially crucial as the world's oil reserves are finite, and the extraction and processing of petroleum often lead to environmental degradation.

Secondly, biobased foams are biodegradable. Unlike their petroleum-based counterparts, which can take hundreds of years to decompose, biobased foams can break down naturally over time, reducing the amount of waste in landfills and minimizing the risk of soil and water pollution.

Additionally, the production of biobased foams often involves less energy-intensive processes. This results in lower carbon emissions and a smaller ecological footprint compared to traditional foam manufacturing methods.

Applications of Biobased Foams

Biobased foams have a wide range of applications across various industries. Here are some notable uses:

- Packaging: These foams are ideal for packaging materials, offering excellent cushioning and protection for fragile items. They provide an eco-friendly alternative to traditional polystyrene foam, which is notoriously difficult to recycle.

- Construction: In the construction industry, biobased foams can be used as insulation materials. They offer similar thermal properties to conventional foam insulators but with a reduced environmental impact. This makes them a sustainable choice for green building projects.

- Furniture: Furniture manufacturers are increasingly turning to biobased foams for seating and cushioning. These foams provide comfort while reducing the ecological footprint of furniture production.

- Automotive: The automotive sector is also exploring the use of biobased foams for various components. From soundproofing to impact absorption, these foams offer lightweight and sustainable solutions for vehicle manufacturing.

- Medical: In the medical field, biobased foams are used in wound care products and as padding for medical devices. Their biocompatibility and biodegradability make them a preferred choice over synthetic materials.

Performance and Durability

A common concern with biobased products is their performance and durability compared to traditional materials. However, biobased foams have made significant advancements in recent years, offering comparable or even superior properties in terms of strength, flexibility, and resilience.

Through careful formulation and manufacturing processes, biobased foam producers have been able to create products that meet or exceed the performance standards of petroleum-based foams. This ensures that businesses and consumers can make the switch to more sustainable options without compromising on quality.

Challenges and Future Prospects

While biobased foams present a promising solution, there are still challenges to overcome. One of the main hurdles is the initial cost. Biobased foams often have a higher production cost compared to petroleum-based foams, which can be a barrier for widespread adoption.

However, as demand for sustainable products grows and production processes become more efficient, the cost of biobased foams is expected to decrease. Additionally, with increasing awareness and support for eco-friendly initiatives, governments and organizations are offering incentives and grants to promote the use of renewable materials.

The future of biobased foams looks bright, with ongoing research and development focused on improving their performance, expanding their applications, and further reducing their environmental impact. As technology advances, we can expect to see even more innovative uses for these sustainable materials.

Sustainable Production Practices

To ensure the sustainability of biobased foam production, manufacturers are adopting responsible practices. This includes using renewable energy sources for manufacturing processes, implementing waste reduction strategies, and optimizing transportation routes to minimize carbon emissions.

Furthermore, many biobased foam producers are committed to fair labor practices and social responsibility. They ensure safe working conditions, fair wages, and support local communities by sourcing raw materials from sustainable farms and supporting local economies.

Case Studies: Real-World Applications

Let's take a look at some successful implementations of biobased foams in various industries:

- Packaging Industry: A leading e-commerce company has switched to biobased foam packaging for its products. This change not only reduces their environmental impact but also provides excellent protection for their items during transit.

- Construction Sector: Green building projects are increasingly incorporating biobased foam insulation. A recent study showed that buildings using these foams achieved significant energy savings and reduced their carbon footprint by up to 20%.

- Automotive Manufacturers: Some automotive companies are using biobased foams for interior components, such as headliners and door panels. This not only reduces weight but also aligns with their sustainability goals.

Tips for Consumers

As a consumer, you can play a vital role in promoting the use of biobased foams. Here are some tips to consider:

- Look for products packaged in biobased foam. Support companies that prioritize sustainability.

- Choose furniture and home goods made with biobased foam fillings. They offer comfort and an eco-friendly alternative.

- When purchasing electronics or appliances, opt for brands that use biobased foam for packaging and insulation.

- Spread awareness about the benefits of biobased foams. Educate your friends and family about sustainable choices.

Conclusion

Biobased foams offer a compelling solution to reduce our reliance on petroleum-based products. With their environmental benefits, diverse applications, and improving performance, they are a viable and sustainable alternative. As consumers and businesses continue to embrace eco-friendly practices, biobased foams will play a crucial role in creating a greener future.

Are biobased foams as durable as petroleum-based foams?

+Yes, biobased foams have made significant advancements in durability. Modern formulations ensure they can match or even surpass the performance of traditional foams, making them a reliable choice for various applications.

How do biobased foams contribute to a circular economy?

+Biobased foams support a circular economy by being biodegradable and easily recyclable. They can be broken down naturally or processed into new products, reducing waste and promoting a sustainable cycle.

What are the potential health benefits of using biobased foams?

+Biobased foams are often free from harmful chemicals and toxins commonly found in petroleum-based foams. This makes them a safer choice for both consumers and the environment, reducing the risk of exposure to toxic substances.

Can biobased foams be customized for specific applications?

+Absolutely! Biobased foam manufacturers can tailor their products to meet specific requirements. Whether it’s for packaging, insulation, or cushioning, they can adjust properties like density, flexibility, and resilience to suit different needs.