8 Hacks For Flawless 3D Prints: Unlock Expertise Today!

Introduction

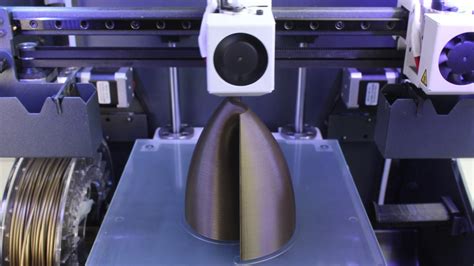

Welcome to the world of 3D printing, where creativity meets technology! In this blog post, we’ll explore eight incredible hacks that will take your 3D printing skills to the next level. Whether you’re a seasoned pro or a beginner, these tips and tricks will help you achieve flawless prints and unlock your full potential as a 3D printing expert. So, let’s dive right in and discover the secrets to mastering this exciting technology!

Hack 1: Calibrate Your Printer for Precision

Calibration is Key The first step towards flawless 3D prints is ensuring your printer is properly calibrated. Calibration ensures that your printer’s movements are precise and accurate, resulting in high-quality prints. Here’s a simple guide to calibrating your 3D printer:

Level the Build Plate: Start by ensuring your build plate is perfectly level. An uneven surface can lead to print failures and uneven layers. Use a piece of paper or a feeler gauge to adjust the build plate until it’s just right.

Adjust Z-Axis Height: Next, adjust the Z-axis height to ensure proper bed adhesion. This step is crucial for preventing prints from lifting or warping. Most printers have an auto-leveling feature, but manual adjustment may be necessary for optimal results.

Calibrate Extrusion: Calibrate your extruder to ensure the right amount of filament is being fed into the print. Over-extrusion or under-extrusion can cause issues like stringing or weak prints. Use a calibration cube or a similar test print to fine-tune your extrusion settings.

Hack 2: Choose the Right Filament

The Power of Filament Selection The type of filament you choose can greatly impact the quality of your 3D prints. Different filaments have unique properties, and selecting the right one for your project is essential. Here are some tips:

- PLA (Polylactic Acid): PLA is a popular choice for beginners due to its ease of use and low warping. It’s perfect for detailed prints and offers a wide range of colors.

- ABS (Acrylonitrile Butadiene Styrene): ABS is known for its strength and durability. It’s an excellent choice for functional parts and prototypes. However, ABS requires a heated bed and a well-ventilated printing area.

- PETG (Polyethylene Terephthalate Glycol): PETG combines the best of both PLA and ABS. It’s strong, flexible, and less prone to warping. PETG is a great all-around filament for various projects.

- Specialty Filaments: Explore specialty filaments like flexible TPU, conductive PLA, or even wood-filled filaments for unique and innovative prints.

Hack 3: Optimize Your Slicer Settings

Slicer Settings: The Fine-Tuning Process The slicing software you use plays a vital role in the quality of your 3D prints. Optimizing your slicer settings can make a significant difference. Here are some key adjustments to consider:

- Layer Height: Experiment with different layer heights to find the perfect balance between print speed and detail. Lower layer heights result in smoother surfaces but slower prints.

- Infill Density: Adjust the infill density to balance strength and material usage. Higher infill densities make your prints stronger but use more filament.

- Support Settings: Configure support settings to ensure your overhangs and complex geometries are properly supported during printing. Consider the angle and density of your supports.

- Print Speed: Adjust the print speed to match the complexity of your model. Slower speeds can improve print quality, especially for detailed or delicate prints.

Hack 4: Master Bed Adhesion

The Art of Bed Adhesion Proper bed adhesion is crucial for successful 3D prints. Here are some techniques to ensure your prints stick to the build plate:

- Use Adhesive Aids: Apply adhesive aids like hairspray, glue sticks, or 3D printing bed adhesives to the build plate. These aids create a sticky surface, helping your first layer adhere securely.

- First Layer Calibration: Ensure your first layer is calibrated perfectly. A well-calibrated first layer sets the foundation for a successful print.

- Heated Bed Temperature: Adjust the heated bed temperature to the recommended range for your filament. Different filaments require specific temperatures for optimal adhesion.

- Bed Leveling: Regularly check and adjust your bed leveling to maintain a consistent distance between the nozzle and the build plate.

Hack 5: Maintain Consistent Filament Flow

Ensuring Smooth Filament Flow Maintaining a consistent filament flow is essential for avoiding issues like under-extrusion or clogs. Here’s how you can achieve smooth filament flow:

- Check Filament Diameter: Ensure your filament’s diameter matches the recommended size for your printer. Even a slight variation can affect extrusion.

- Filament Guide Tubes: Use high-quality filament guide tubes to ensure a smooth and consistent flow of filament to the extruder.

- Retract Settings: Optimize your retract settings to minimize the chances of stringing or oozing. Adjust the retract distance and speed to find the right balance.

- Regular Cleaning: Clean your nozzle and extruder regularly to prevent clogs and ensure a consistent flow of filament.

Hack 6: Optimize Cooling for Better Prints

The Impact of Cooling Proper cooling can significantly improve the quality of your 3D prints, especially for detailed or delicate models. Here’s how to optimize cooling:

- Active Cooling: Use active cooling systems like fans or air ducts to cool your prints during and after printing. This helps prevent warping and reduces the risk of print failures.

- Cooling Settings: Adjust the cooling settings in your slicer software. Control the fan speed and placement to cool specific areas of your print effectively.

- Layer Cooling: Allow sufficient time for each layer to cool before starting the next one. This prevents warping and ensures better adhesion between layers.

- Material-Specific Cooling: Different filaments require different cooling strategies. Research the optimal cooling settings for the filament you’re using.

Hack 7: Post-Processing Techniques

Enhancing Your Prints with Post-Processing Post-processing can take your 3D prints to the next level by improving their appearance and functionality. Here are some popular post-processing techniques:

- Sandpaper and Files: Use sandpaper and files to smooth out rough surfaces and remove support marks. Start with a coarse grit and gradually move to finer grits for a polished finish.

- Acetone Vapor Smoothing: For ABS prints, acetone vapor smoothing can create a glossy, smooth finish. Be cautious and ensure proper ventilation when using this technique.

- Painting and Finishing: Add color and personality to your prints by painting them. Use appropriate paints and primers for a professional-looking finish.

- Chemical Smoothing: Explore chemical smoothing techniques like isopropyl alcohol (IPA) smoothing for PLA prints. This process can enhance the surface quality and reduce visible layer lines.

Hack 8: Regular Maintenance and Upgrades

The Importance of Maintenance and Upgrades Regular maintenance and upgrades are essential to keep your 3D printer in top shape. Here are some key maintenance tasks:

- Clean and Lubricate: Regularly clean your printer’s moving parts and lubricate them as needed. This ensures smooth and precise movements.

- Check Nozzle and Hotend: Inspect your nozzle and hotend for clogs or damage. Clean or replace them as necessary to maintain print quality.

- Update Firmware: Keep your printer’s firmware up to date to access the latest features and improvements.

- Consider Upgrades: Explore upgrades like dual extruders, larger build volumes, or advanced features like auto-leveling sensors. Upgrades can enhance your printing experience and capabilities.

Conclusion

Congratulations! You’ve unlocked the secrets to flawless 3D prints with these eight expert hacks. By calibrating your printer, choosing the right filament, optimizing slicer settings, mastering bed adhesion, and implementing proper maintenance, you’ll achieve exceptional results. Remember, practice makes perfect, so keep experimenting and refining your skills. Happy printing, and may your 3D printing journey be filled with endless creativity and success!

FAQ

How often should I calibrate my 3D printer?

+It’s recommended to calibrate your 3D printer before each major print job or whenever you notice a decline in print quality. Regular calibration ensures consistent and precise prints.

Can I use multiple filaments in one print?

+Yes, you can use multiple filaments in a single print by utilizing a dual extruder setup. This allows you to create multi-color or multi-material prints with ease.

How do I know if my filament is compatible with my printer?

+Check your printer’s specifications and recommendations for compatible filament types. Additionally, research online forums and communities to gather insights from other users.

What are some common issues with bed adhesion, and how can I fix them?

+Common issues include warping, lifting, or poor adhesion. To fix these, ensure proper bed leveling, use adhesive aids, and adjust your heated bed temperature.

How can I improve the surface quality of my 3D prints?

+To enhance surface quality, consider post-processing techniques like sanding, acetone vapor smoothing, or chemical smoothing. These techniques can reduce visible layer lines and create a smoother finish.