8 Easy Steps To Make Your Pro 832 Tap Drill Now

Getting Started with Your Pro 832 Tap Drill

Are you ready to dive into the world of precise drilling and tapping? The Pro 832 Tap Drill is a powerful tool that can take your projects to the next level. Whether you're a DIY enthusiast or a professional, this guide will walk you through the process of using this tool effectively. Let's get started!

Step 1: Understanding the Pro 832 Tap Drill

The Pro 832 Tap Drill is a versatile tool designed for creating precise threads in various materials. It consists of a tap, which cuts the threads, and a drill bit, which creates the hole. This combination allows you to prepare the perfect hole for threading, ensuring a secure and strong connection.

Step 2: Safety First

Before you begin, ensure you have the necessary safety gear. This includes safety goggles to protect your eyes from flying debris and gloves to prevent any injuries. Always work in a well-ventilated area, especially when drilling or tapping metal, as it can produce fine particles that are harmful if inhaled.

Step 3: Choose the Right Drill Bit

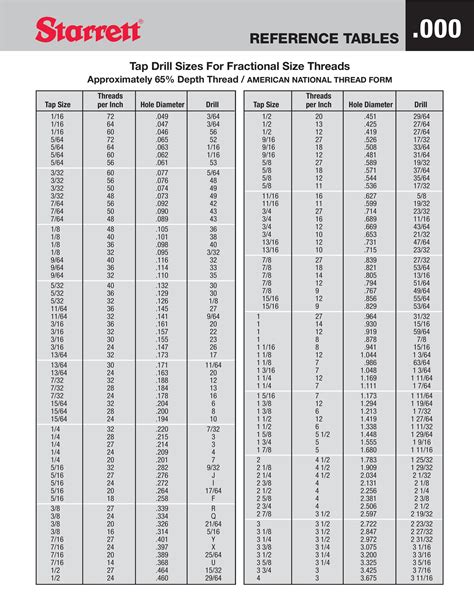

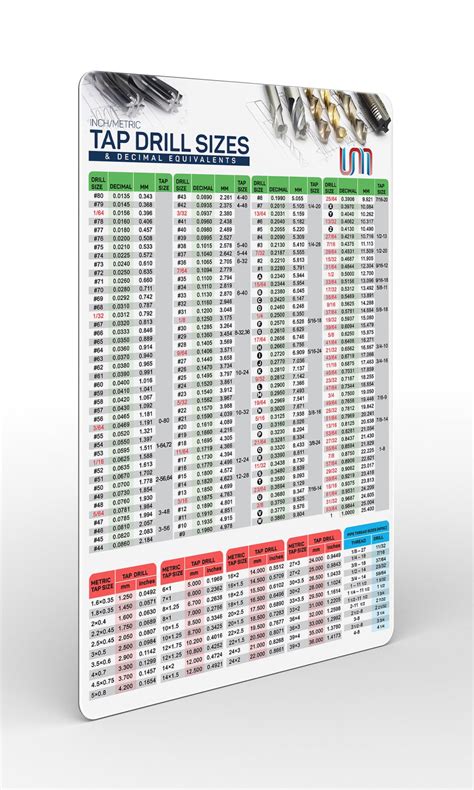

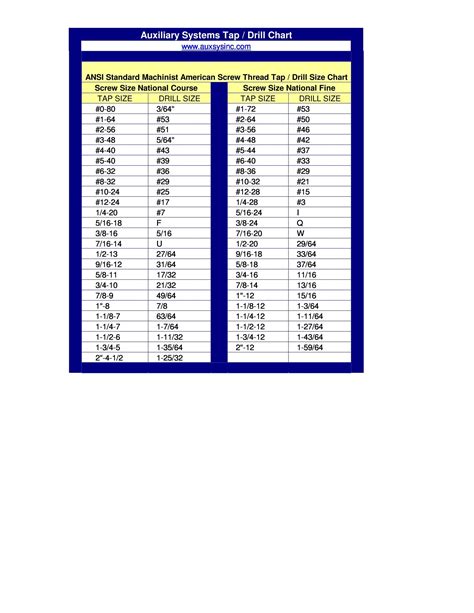

Selecting the appropriate drill bit is crucial for a successful outcome. The size of the drill bit should correspond to the tap you'll be using. Refer to the manufacturer's guidelines or consult a tap and drill bit size chart to make the right choice. Using the correct drill bit ensures a clean and accurate hole, making the tapping process easier.

Step 4: Marking and Clamping

Properly marking and clamping your workpiece is essential for accurate drilling. Use a marker or a scribe to indicate the exact spot where you want to drill. Then, securely clamp your workpiece to a stable surface. This prevents any movement during drilling, ensuring a straight and precise hole.

Step 5: Drilling the Hole

Now it's time to drill! Set your drill to the appropriate speed and depth for the material you're working with. Start drilling slowly and increase speed gradually. Apply gentle pressure and let the drill do the work. Avoid forcing the drill, as this can cause the bit to break or create an uneven hole.

Step 6: Deburring the Hole

After drilling, you may notice some sharp edges or burrs around the hole. These can interfere with the tapping process and even damage your tap. Use a deburring tool or a file to smooth out these edges. A clean and burr-free hole ensures a smooth and easy tapping experience.

Step 7: Selecting the Right Tap

Just like choosing the right drill bit, selecting the correct tap is crucial. The tap size should match the drill bit size, and the thread type should be suitable for your project. Different materials and applications require different taps. Refer to the manufacturer's guidelines or consult a tap size chart to make the right choice.

Step 8: Tapping the Hole

Now for the exciting part - tapping! Securely attach the tap to your drill or tap handle. Start tapping slowly, applying gentle pressure. Ensure the tap is perpendicular to the hole to create straight and even threads. As you tap, you may need to back the tap out occasionally to clear any chips or debris. Keep tapping until you've reached the desired depth.

Note: Always follow the recommended tapping speed and depth for your specific tap and material. Over-tapping can damage the threads, while under-tapping may result in weak connections.

Maintenance and Care

Regular maintenance ensures the longevity of your Pro 832 Tap Drill. After each use, clean the tap and drill bit with a wire brush or a cleaning solvent to remove any debris or residue. Store them in a dry and safe place to prevent rusting. Keep the drill and tap sharp by periodically sharpening them using a tap and die grinder or a sharpening stone.

Conclusion

With these eight easy steps, you're now equipped to tackle any tapping project with confidence. The Pro 832 Tap Drill offers precision and versatility, making it an essential tool for any workshop. Remember to prioritize safety, choose the right tools, and maintain your equipment for optimal performance. Happy drilling and tapping!

What materials can I use the Pro 832 Tap Drill on?

+

The Pro 832 Tap Drill is suitable for a wide range of materials, including wood, plastic, and various metals. However, it’s important to choose the right tap and drill bit for each material to ensure optimal results.

Can I use the Pro 832 Tap Drill for large-scale projects?

+

Absolutely! The Pro 832 Tap Drill is designed for both small and large-scale projects. Its versatility and precision make it an excellent choice for a wide range of applications, from DIY projects to professional construction.

How often should I sharpen my tap and drill bit?

+

The frequency of sharpening depends on the usage and material. As a general guideline, inspect your tap and drill bit after each use. If you notice any signs of wear or dullness, it’s time to sharpen. Regular sharpening ensures optimal performance and prolongs the life of your tools.

What safety precautions should I take when using the Pro 832 Tap Drill?

+

Safety is paramount when using any power tool. Always wear safety goggles and gloves to protect yourself from flying debris and sharp edges. Work in a well-ventilated area, especially when drilling or tapping metal. Keep a safe distance from the drill and tap to avoid any accidents.

Where can I find more information and support for my Pro 832 Tap Drill?

+

For detailed specifications, troubleshooting, and additional support, refer to the manufacturer’s website or user manual. You can also join online communities or forums dedicated to power tools, where you can find valuable tips and advice from experienced users.