5 Ultimate Tips To Design The Perfect A10 Warthog Bullet

Designing the perfect A10 Warthog bullet requires a meticulous approach, considering the weapon's iconic status and its crucial role in modern warfare. This guide will delve into the essential aspects of creating an optimal A10 bullet, ensuring it meets the highest standards of performance and reliability.

1. Material Selection

The choice of material is fundamental to the bullet's performance. Copper-jacketed lead cores are a popular choice due to their high density and excellent penetration capabilities. The copper jacket provides durability and accuracy, ensuring the bullet maintains its shape during flight.

Additionally, tungsten and depleted uranium offer exceptional penetrative power and stability, making them ideal for armor-piercing rounds. These materials can be used in conjunction with a lead core to create a highly effective bullet.

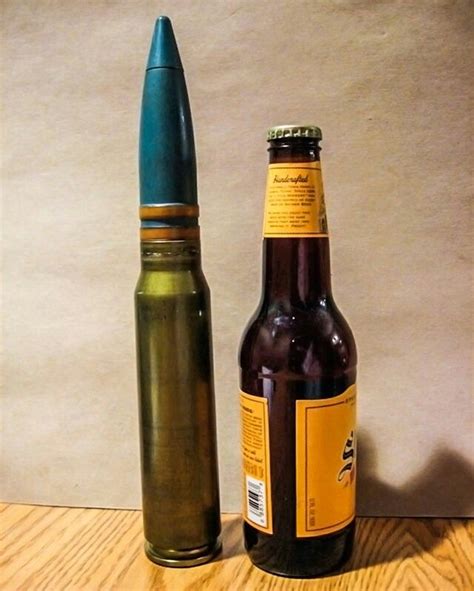

2. Bullet Weight and Caliber

The weight and caliber of the bullet directly impact its performance. A heavier bullet tends to have more kinetic energy, resulting in increased penetration and stopping power. However, it's crucial to balance weight with the gun's capabilities to avoid overloading the weapon.

The caliber, or the bullet's diameter, is equally important. A larger caliber allows for a wider range of bullet designs and can accommodate heavier payloads. It's essential to choose a caliber that aligns with the A10 Warthog's specifications to ensure optimal performance.

3. Tip Design

The tip of the bullet plays a critical role in its performance. A pointed tip reduces air resistance, allowing the bullet to travel faster and farther. This design is particularly effective for long-range engagements.

For close-range combat, a flat-nosed or hollow-point tip can be more effective. These designs increase the bullet's drag, causing it to slow down and transfer more energy upon impact, resulting in greater stopping power.

4. Powder Charge and Muzzle Velocity

The amount of powder used to propel the bullet, known as the powder charge, significantly affects the bullet's velocity. A higher powder charge results in a faster muzzle velocity, which can lead to increased accuracy and range.

However, it's crucial to strike a balance, as an excessive powder charge can strain the gun's mechanisms and reduce overall accuracy. The A10 Warthog's design should dictate the optimal powder charge for maximum performance.

5. Lubrication and Cleaning

Proper lubrication is essential to ensure smooth operation and prolong the life of the A10 Warthog. Lubricating the bullet reduces friction between the bullet and the gun's barrel, improving accuracy and reducing wear and tear.

Regular cleaning is also vital. Over time, residue and fouling can build up in the barrel, affecting the bullet's performance. Using a suitable cleaning kit and following a regular maintenance schedule will keep the A10 Warthog in optimal condition.

🚨 Note: It's crucial to adhere to local laws and regulations when designing and using ammunition. Always prioritize safety and follow proper guidelines.

Conclusion

Designing the perfect A10 Warthog bullet involves a careful consideration of various factors, from material selection to lubrication. By optimizing these elements, you can create a bullet that maximizes the A10's potential, ensuring accurate and powerful performance in the field. Remember, safety should always be the top priority when handling firearms and ammunition.

Can I use alternative materials for the bullet core?

+

While copper-jacketed lead is a popular choice, alternative materials like tungsten and depleted uranium can offer improved performance for specific applications. However, it’s important to consider the legal and environmental implications of using these materials.

How do I determine the optimal powder charge for my A10 Warthog?

+

The optimal powder charge depends on the specific A10 Warthog model and the desired muzzle velocity. It’s recommended to consult the gun’s manual or seek advice from a firearms expert to determine the appropriate charge for your weapon.

What cleaning products are recommended for the A10 Warthog?

+

Using a mild solvent and a soft-bristled brush is recommended for cleaning the A10 Warthog. Avoid using harsh chemicals or abrasive materials that could damage the gun’s finish or internal components. Regular cleaning and maintenance will ensure the longevity of your weapon.